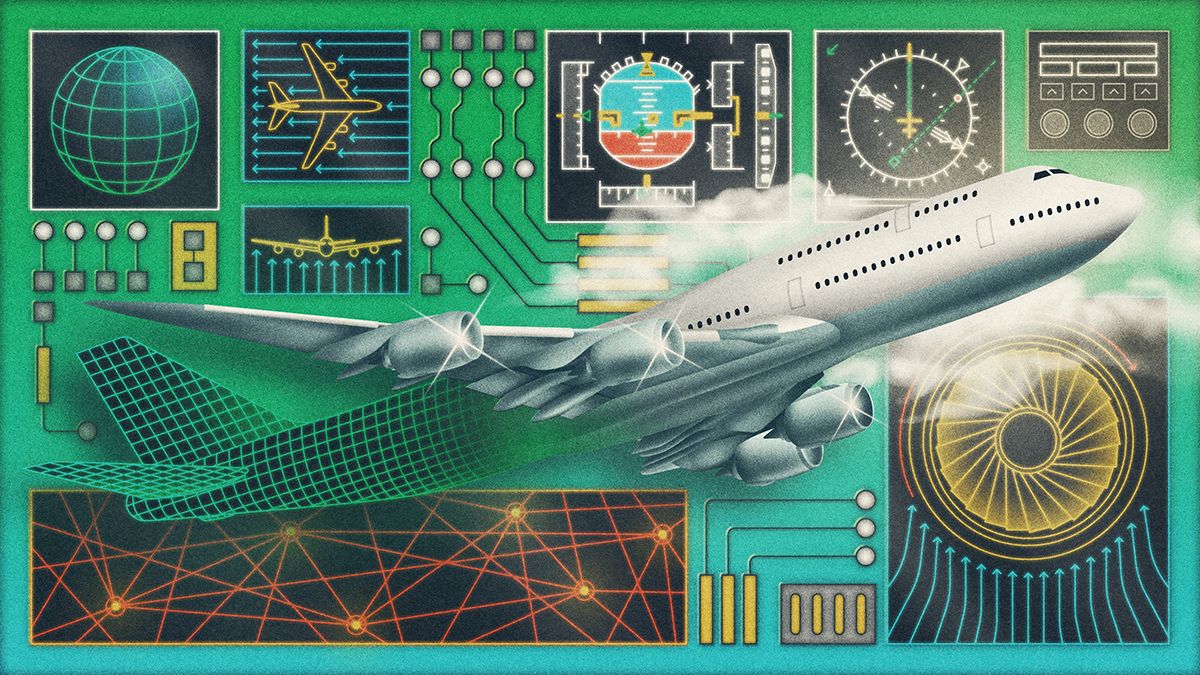

Increased increased is a reason that A350-900 can fly New York to Soginapore“The longest flight of the day – with two engines. Another key factor is that in the last 30 years, aircraft engines have fundamentally become more effective, even if the basic turbine technology has the same.

Improvements, on the other hand, are advances in the manufacture of motorbike blades made with carbon fiberglass compounds, twice and significantly lighter than titanium blades; improved cooling systems; And during flight controls that control crucial data with sophisticated control programs, such as air pressure, temperature, airspeed and more. The optimal location of engines on the wing has also been refined.

“If you examine the road 747, you can give the same boost on 20 percent and 30 percent of the engines that are 20 to 30 years ago.

The difference consists of using the air flow. Turbojet motors used in older planes are strengthened in the core of the engine and the combustion chambers, creating thrust away by throwing away gases at high speed. This process used more energy and was much louder than newer engines.

Modern long-aircraft use those who are called high-by-bypass engines, which allows a large volume of air to emit at the core of the engine. Then the push, then creates large fans of the engine front. The part can be seen directly by looking at, against the escaped flight. This design has greatly improved the efficiency of the engine that increased the air of the bypass.

New engines create extra power. The Dreamliner throws bypass electric motor, Genxa, Boeing 737 is as wide as the fuselage. Depending on the Ger’s website, the engine has a 10: 1 bypass ratio, which means it goes 10 times more air outside the engine, rather than at the core of the combustion engine.

Computer designs have also been more efficient and stronger blades so that it can be rotated in 30,000 and 40,000 rpm. “You have to have structures that can bear this type of rotation and stress that can bear this type,” he said. The ceramic materials used in the engine nucleus allows higher internal temperatures than Nickel’s super alloy metals, which are currently used in most major motors.

The use of light compound materials, namely carbon fibers, plane wings and fuselage has significantly reduced the overall weight of the aircraft. An aircraft weighs less, less energy is needed to votate.

The general design of these aircraft are more aerodynamic. The A350 and Dreamliner varieties are thinner than previous generations, and the design of fuselage, especially the dolphin nose of Delfin, especially creates less drag.

In the location, new technologies simplifies pilot control pilots and problem solving feedback through advanced systems that help reduce the pilot workload and increase performance. Today’s long-air aircraft allow semi-autonomous flights, technology already completely self-employed for autonomous flights, as well as for large commercial aircraft.

The passenger experience has improved, although the rhythm of this technology may not be maintained with the same aircraft. The largest difference between current commercial aircraft and previous generations is the ability to control the pressure, moisture and air circulation. “(When) Boeing produced in 787, they could moisten the atmosphere,” Grant says. “It’s only a huge improvement for people, you know, after a 9- or 10 hour flight to feel like you had corn flows on the nose.”

Another major improvement over the long-flight, according to the grants? Today’s Airline Wi-Fi It’s really good.

The version of this story appeared originally Fit.